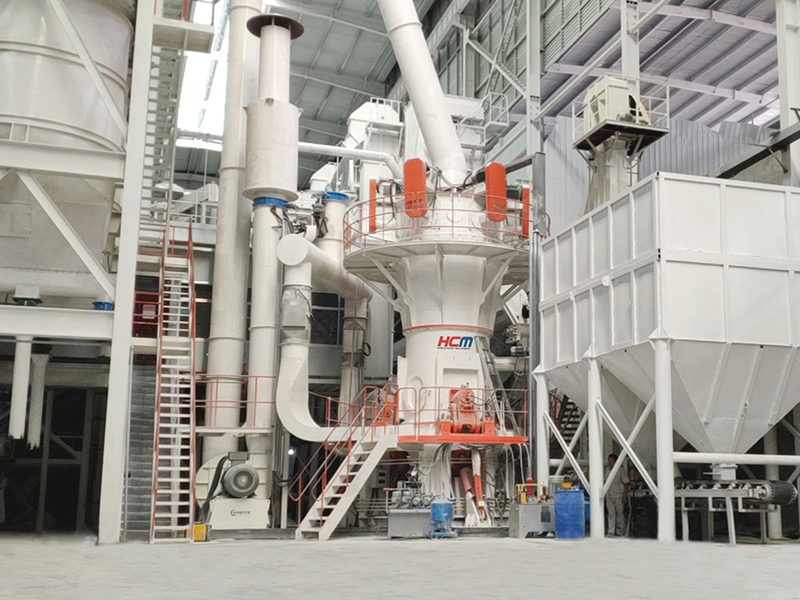

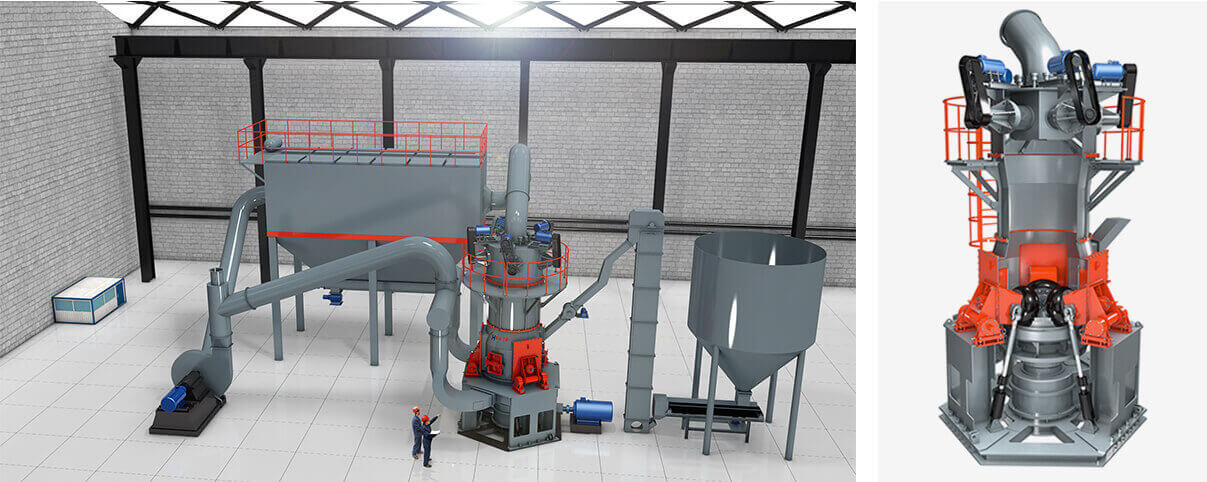

Ukusebenza kahle kokugaya okuphezulu nokonga amandla.Umthamo weyunithi eyodwa ungafinyelela ku-40t/h.Ukusebenzisa izigaba ezingabodwa nezinamakhanda amaningi, asikho isidingo sokusebenzisa ukuhlukaniswa komoya kwesibili nokuhlukaniswa, futhi kungonga ukusetshenziswa kwamandla okungama-30% -50% kunezigayo ezijwayelekile.

qonda

UDINGA ISIXAZULULO?Ukuze uthole ulwazi olwengeziwe lokugaya noma isicelo sekhotheshini sicela uxhumane nathi.

UphenyoXhumana nathi

Siyakwamukela ku-Guilin HongchengI-Guilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Ucingo:86-0773-3568321

- Ikheli:Yangtang Shanshui Industrial Park, Xicheng Economic Development Zone, Guilin City, Guangxi Province, China

- I-imeyili:hcmkt@hcmilling.com

© Copyright - 2010-2023 : Wonke Amalungelo Agodliwe.Imikhiqizo Eshisayo - Imephu yesayithi

Ugaya Amalahle, I-Powder Paint Grinding Mill From China Supplier, I-Ultra Fine Mill, I-Ultra Fine Grinding Mill, I-Mill Grinder, I-Petroleum Coke Vertical Roller Mill,

Ugaya Amalahle, I-Powder Paint Grinding Mill From China Supplier, I-Ultra Fine Mill, I-Ultra Fine Grinding Mill, I-Mill Grinder, I-Petroleum Coke Vertical Roller Mill,