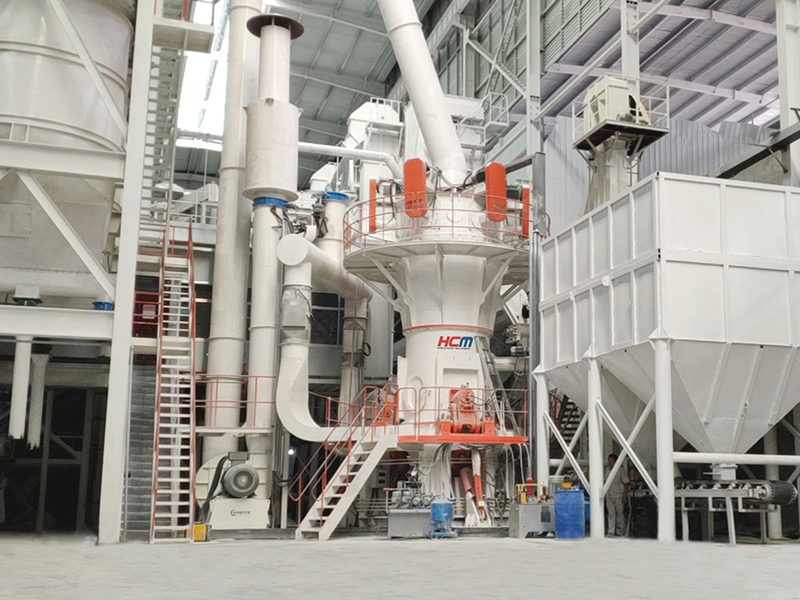

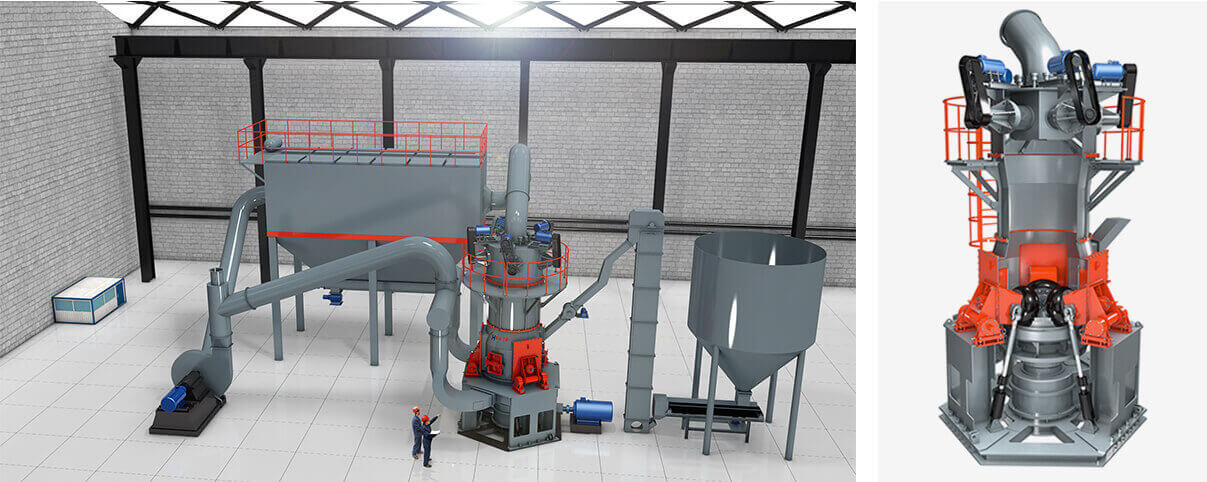

Ukusebenza okuphezulu kokusila kunye nokonga amandla.Umthamo weyunithi enye unokufikelela kwi-40t / h.Ukusebenzisa i-classifiers eyodwa kunye ne-multi-head-head, akukho mfuneko yokusebenzisa ukuhlukana komoya wesibini kunye nokuhlelwa, kwaye kunokugcina i-30% -50% yokusetyenziswa kwamandla ngaphezu kwee-mills eziqhelekileyo.

ukuqonda

UFUNA ISIcombululo?Ngolwazi oluthe vetshe lokusila okanye isicelo sekowuti nceda uqhagamshelane nathi.

UkubuzaQhagamshelana nathi

Wamkelekile Guilin HongchengGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Ifowuni:86-0773-3568321

- Idilesi:Yangtang Shanshui Industrial Park, Xicheng yoPhuhliso lwezoQoqosho Zone, Guilin City, kwiPhondo Guangxi, China

- I-imeyile:hcmkt@hcmilling.com

© Copyright - 2010-2023 : Onke Amalungelo Agciniwe.Iimveliso ezishushu - Imephu yesiza

UkuSila amalahle, Ipeyinti yomgubo yokuSila iMill evela kuMboneleli waseTshayina, Ultra Fine Mill, Ultra Fine Grinding Mill, I-Mill Grinder, IPetroleum Coke nkqo Roller Mill,

UkuSila amalahle, Ipeyinti yomgubo yokuSila iMill evela kuMboneleli waseTshayina, Ultra Fine Mill, Ultra Fine Grinding Mill, I-Mill Grinder, IPetroleum Coke nkqo Roller Mill,