Khalase ea litšila ke mofuta oa litšila tsa malapeng, boteng ba eona ha bo bake feela kotsi le tšitiso ho tlhahiso le bophelo ba batho, empa hape bo tlisa tšilafalo tikolohong, bo nka mobu oa bohlokoa, 'me bo eketsa mojaro oa tikoloho.Ho hakanngoa hore China e hlahisa lithane tse ka bang limilione tse 3.2 tsa likhalase tsa litšila selemo se seng le se seng, e leng karolo ea 2% ea kakaretso ea matlakala a 'masepala.Ka ho matlafatsoa ha matla a naha a felletseng le ntlafatso ea maemo a bophelo a batho, kakaretso ea likhalase tsa litšila le eona e eketsehile.Tabeng ea ho nchafatsa le ho sebelisoa ha likhalase tse litšila, linaha tse ling tse tsoetseng pele United Kingdom le United States li finyelletse liphello tse babatsehang.Linaha tsa Europe le Amerika li atlehile ho sebelisa likhalase tsa litšila mererong ea kaho, e leng mokhoa o atlehang oa ho sebelisa likhalase tse ngata tse senyehileng.Hobane mefuta eohle ea likhalase tsa litšila ha e hloke ho hlophisoa, ha ho hlokahale hore ho be le mebala.Mohlala, khalase ea litšila e sebetsoa e le thepa ea mokhabiso oa moaho ka Mosaic.Joalo ka moetsi oa leloala la likhalase tsa litšila, leloala la khalase la litšila le hlahisoang ke HCM Machinery le fana ka thuso e ntle ea lisebelisoa bakeng sa ho sebelisoa hape ha likhalase tsa litšila.Kajeno, re tla hlahisa mokhoa oa ho hlahisa litšila tsa khalase ea Mosaic.

1. Molemo oa lefika la phosphate: Ho rua molemo oa lejoe la phosphate ke mohato oa pele oa ho lokisa lejoe la phosphate, leo sepheo sa lona e leng ho arola liminerale tse molemo le litšila tse mafikeng a phosphate ka mekhoa ea ’mele le ea lik’hemik’hale.Mekhoa e tloaelehileng ea ho rua molemo e kenyelletsa karohano ea matla a khoheli, ho phaphamala le karohano ea makenete.Karohano ea matla a khoheli e sebelisa phapang ea boima ba liminerale ka har'a ore bakeng sa karohano, flotation e sebelisa phapang ea buoyancy ea liminerale ka har'a tšepe bakeng sa karohano, 'me karohano ea makenete e sebelisa phapang ea makenete ea liminerale ka har'a tšepe bakeng sa karohano.

2. Ho sila le ho sila ha phosphate rock: phosphate rock after beneficiation, e hloka ho siloa le ho sila kalafo, e le ho lokolla liminerale tse molemo ka har'a tšepe.Ho sila hangata ho sebelisoa sesila sa mohlahare, sebotlolo sa cone le lisebelisoa tse ling ho pshatla lejoe la phosphate ka boholo bo loketseng.Ho sila ke tšebeliso ea tlhahiso ea leloala le leholo le ho sebetsa mochini oa phofo ea phosphate ho sila tšepe e sithabetseng, e le hore e finyelle litlhoko tse hlokahalang tsa fineness.

3. Leaching ea lefika la phosphate: Leaching ke mohato oa bohlokoa ho lokisoeng ha lejoe la phosphate, leo ka lona metsoako e molemo e kang phosphate e ka qhibilihang ho tloha holim'a tšepe.Mekhoa e sebelisoang hangata e kenyelletsa leaching ea acid, alkali leaching le oxidation leaching.Acid leaching e sebelisa tharollo e nang le asiti ho qhibilihisa phosphate, alkaline leaching e sebelisa tharollo ea alkaline ho qhibiliha phosphate, 'me oxidative leaching e sebelisa oxidizing agent ho qhibilihisa phosphate.

4. Ho na le pula le ho tlhotla ha phosphate ores: Ka mor'a ho kolobisa, tharollo ea likarolo tse molemo tse kang phosphate e hloka ho kolobisoa le ho sefshoa ho arola lihlahisoa tse tiileng tsa phosphate.Pula ke ts'ebeliso ea sesebelisoa sa precipitating ho fetolela karolo ea phosphate ea tharollo hore e be pula e tiileng, 'me ho tlhotla ke ho arola sediment ho tsoa ho tharollo ka lisebelisoa tsa ho sefa.

5. Ho omisa le ho kolobisoa ha lejoe la phosphate: Ka mor'a hore seretse se sefshoe, se hloka ho omisoa le ho siloa ho fumana sehlahisoa se felileng sa phosphate.Ho omisa ke tšebeliso ea lisebelisoa tsa ho omisa ho etsa mouoane oa metsi sediment, 'me sintering ke ho omisa sediment ka mocheso o phahameng oa sintering, e le hore e thehe likaroloana tse teteaneng tsa phosphate.

6. Phekolo ea masela a phosphate ore: ts'ebetso ea phosphate ore process e tla hlahisa palo e itseng ea mehatla, mehatla e na le liminerale tse sa ntšoang le litšila.E le ho fokotsa tšilafalo ea tikoloho le ho senyeha ha lisebelisoa, li-tailings li hloka ho phekoloa.Mekhoa e tloaelehileng ea kalafo ea li-tailings e kenyelletsa ho bokellana ha li-tailings, ho etsa li-tailings hape le ts'ebeliso e felletseng.

Ts'ebetso ea tlhahiso ea likhalase tsa litšila tsa khalase ea Mosaic: mokhoa oa sintering le mokhoa oa ho qhibiliha o sebelisoa ka kakaretso, 'me mokhoa oa tlhahiso oa mokhoa oa sintering le oa ceramic Mosaic o ts'oana.Mokhoa o ka sehloohong oa tlhahiso ke ho sila khalase ea litšila ka leloala la khalase ho fihlela litlhoko tsa boleng bo botle ba phofo ea khalase, ebe o eketsa palo e itseng ea ntho e khomarelang (inorganic kapa organic can) le moemeli oa mebala kapa moemeli oa decolorizing, mixer ho e kopanya hore e be motsoako o ts'oanang.Motsoako o hatelloa ka libopeho tse fapaneng tsa geometri ka mokhoa o omileng oa ho hatella, 'me' mele o omisitsoeng o romelloa seboping sa lirolara, seboping sa poleiti le kotopo ka mocheso oa likhato tse 800-900 tsa Celsius bakeng sa sintering.Ka kakaretso, e lula sebakeng sa mocheso oa sintering bakeng sa lihora tse 1.5-2.5.Lihlahisoa tse futhumatsang ho tsoa ka sebōping bakeng sa ho hlahlojoa, ho behoa, ho omisoa, ho hlahlojoa, ho paka, polokelo kapa fektheri, lihlahisoa tse sa tšoanelehang li sebelisoa hape.Mokhoa oa ho qhibiliha o thehiloe holim'a khalase ea litšila (palo ea batho ke 25-60%) e le thepa e ka sehloohong e tala, e eketsang palo e itseng ea lehlabathe la silika, feldspar, limestone, soda ash le emulsion agent, coloring agent ka ho sila ha khalase ea litšila. mochine ho kena junifomo tšoanang phofo, 'me joale ka sebōpi se phahameng sa mocheso qhibiliha (mocheso o qhibilihang ke 1400-1500) ho qhibiliha ka mokelikeli o lekanang oa khalase.Mokelikeli oa khalase o phalla ka har'a khalendara 'me o hatelloa ka har'a boloko ea khalase ea boholo bo itseng le sebōpeho, e romelloang sebōping sa ho chesa.Lihlahisoa tse annealed li ka bolokoa kapa tsa tlisoa ka mor'a tlhahlobo, ho beoa le ho paka.

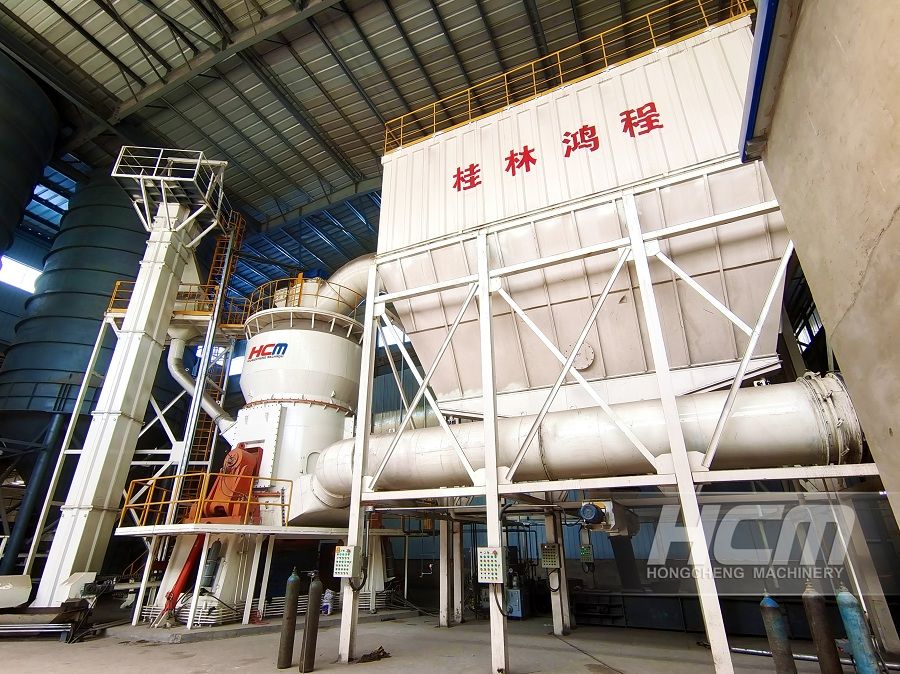

Tšebeliso ea likhalase tse litšila Metsoako ea likhalase e thehiloe holim'a ho sila likhalase tsa litšila hore e be phofo ea khalase.Leloala la khalase ea litšila ke sesebelisoa sa tlhahiso bakeng sa ho lokisa phofo ea khalase.Leloala la likhalase tsa litšila tse hlahisoang keMechine ea HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Nako ea poso: Jan-08-2024