Introduction

Petroleum coke is a product of crude oil separated from heavy oil by distillation and then transformed into heavy oil by thermal cracking. Its main element composition is carbon, accounting for more than 80%. In appearance, it is coke with irregular shape, different sizes, metallic luster and multi void structure. According to the structure and appearance, petroleum coke products can be divided into needle coke, sponge coke, pellet reef and powder coke.

1. Needle coke: it has obvious needle structure and fiber texture. It is mainly used as high power and higher power graphite electrode in steelmaking.

2. Sponge coke: with high chemical reactivity and low impurity content, it is mainly used in aluminum industry and carbon industry.

3. Bullet Reef (spherical coke): it is spherical in shape and 0.6-30mm in diameter. It is generally produced by high sulfur and high asphaltene residue, which can only be used as industrial fuel such as power generation and cement.

4. Powdered coke: produced by fluidized coking process, it has fine particles (diameter 0.1-0.4mm), high volatile content and high thermal expansion coefficient. It can not be directly used in electrode preparation and carbon industry.

Application area

At present, the main application field of petroleum coke in China is electrolytic aluminum industry, accounting for more than 65% of the total consumption. In addition, carbon, industrial silicon and other smelting industries are also the application fields of petroleum coke. As a fuel, petroleum coke is mainly used in cement, power generation, glass and other industries, accounting for a small proportion. However, with the construction of a large number of coking units in recent years, the output of petroleum coke is bound to continue to expand.

1. The glass industry is an industry with high energy consumption, and the fuel cost accounts for about 35% ~ 50% of the glass cost. Glass furnace is an equipment with high energy consumption in glass production line. Petroleum coke powder is used in the glass industry, and the fineness is required to be 200 mesh D90.

2. Once the glass furnace is ignited, it cannot be shut down until the furnace is overhauled (3-5 years). Therefore, it is necessary to continuously add fuel to ensure the furnace temperature of thousands of degrees in the furnace. Therefore, the general pulverizing workshop will have standby mills to ensure continuous production.

Industrial design

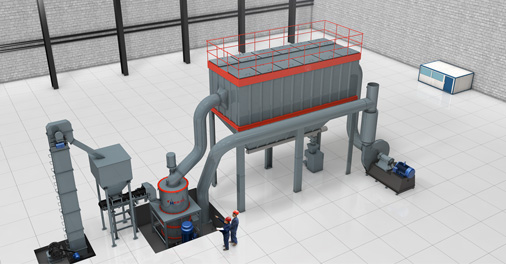

According to the application status of petroleum coke, Guilin Hongcheng has developed a special petroleum coke pulverizing system. For materials with 8% - 15% water content of raw coke, Hongcheng is equipped with professional drying treatment system and open circuit system, which has better dehydration effect. The lower the water content of finished products, the better. This further improves the quality of finished products and is a special pulverizing equipment to meet the consumption of petroleum coke in glass furnace industry and glass industry.

Equipment Selection

HC large pendulum grinding mill

Fineness: 38-180 μm

Output: 3-90 t/h

Advantages and features: it has stable and reliable operation, patented technology, large processing capacity, high classification efficiency, long service life of wear-resistant parts, simple maintenance and high dust collection efficiency. The technical level is at the forefront of China. It is a large-scale processing equipment to meet the expanding industrialization and large-scale production and improve the overall efficiency in terms of production capacity and energy consumption.

HLM vertical roller mill:

Fineness: 200-325 mesh

Output: 5-200T / h

Advantages and features: it integrates drying, grinding, grading and transportation. High grinding efficiency, low power consumption, easy adjustment of product fineness, simple equipment process flow, small floor area, low noise, small dust and less consumption of wear-resistant materials. It is an ideal equipment for large-scale pulverization of limestone and gypsum.

Key parameters of petroleum coke grinding

|

Hardgrove Grindability Index(HGI) |

Initial moisture(%) |

Final moisture(%) |

|

>100 |

≤6 |

≤3 |

|

>90 |

≤6 |

≤3 |

|

>80 |

≤6 |

≤3 |

|

>70 |

≤6 |

≤3 |

|

>60 |

≤6 |

≤3 |

|

>40 |

≤6 |

≤3 |

Remarks:

1. The Hardgrove Grindability Index(HGI) parameter of petroleum coke material is the factor affecting the capacity of grinding mill. The lower the Hardgrove Grindability Index(HGI), the lower the capacity;

The initial moisture of raw materials is generally 6%. If the moisture content of raw materials is greater than 6%, the dryer or mill can be designed with hot air to reduce the moisture content, so as to improve the capacity and quality of finished products.

Service support

Training guidance

Guilin Hongcheng has a highly skilled, well-trained after-sales team with a strong sense of after-sales service. After sales can provide free equipment foundation production guidance, after-sales installation and commissioning guidance, and maintenance training services. We have set up offices and service centers in more than 20 provinces and regions in China to respond to customer needs 24 hours a day, pay return visits and maintain the equipment from time to time, and create greater value for customers wholeheartedly.

After-sale service

Considerate, thoughtful and satisfactory after-sales service has been the business philosophy of Guilin Hongcheng for a long time. Guilin Hongcheng has been engaged in the development of grinding mill for decades. We not only pursue excellence in product quality and keep pace with the times, but also invest a lot of resources in after-sales service to shape a highly skilled after-sales team. Increase efforts in installation, commissioning, maintenance and other links, meet customer needs all day, ensure the normal operation of equipment, solve problems for customers and create good results!

Project acceptance

Guilin Hongcheng has passed ISO 9001:2015 international quality management system certification. Organize relevant activities in strict accordance with the certification requirements, conduct regular internal audit, and continuously improve the implementation of enterprise quality management. Hongcheng has advanced testing equipment in the industry. From casting raw materials to liquid steel composition, heat treatment, material mechanical properties, metallography, processing and assembly and other related processes, Hongcheng is equipped with advanced testing instruments, which effectively ensures the quality of products. Hongcheng has a perfect quality management system. All ex factory equipment are provided with independent files, involving processing, assembly, testing, installation and commissioning, maintenance, parts replacement and other information, creating strong conditions for product traceability, feedback improvement and more accurate customer service.

Post time: Oct-22-2021