Introduction to wollastonite

Wollastonite is a triclinic, thin plate-like crystal, aggregates were radial or fibrous. The color is white, sometimes with light gray, light red color with glass luster, cleavage surface with pearl luster. Hardness is 4.5 to 5.5; density is 2.75 to 3.10g/cm3. Completely soluble in concentrated hydrochloric acid. Under normal circumstances is acid, alkali, chemical resistance. Moisture absorption is less than 4%; low oil absorption, low electrical conductivity, good insulation. Wollastonite is a typical metamorphic mineral, mainly produced in acid rock and limestone contact zone, and Fu rocks, garnet symbiotic. Also found in the deep metamorphic calcite schist, volcanic eruption and some alkaline rocks. Wollastonite is an inorganic needle-like mineral, characterized by non-toxic, chemical corrosion resistance, good thermal stability and dimensional stability, glass and pearl luster, low water absorption and oil absorption, mechanical properties and excellent electrical properties and a certain Reinforcing effect. Wollastonite products is long fiber and easy separation, low iron content, high whiteness. The product is mainly used for polymer-based composites reinforced filler. Such as plastics, rubber, ceramics, coatings, building materials and other industries.

Application of wollastonite

In the ever-changing technology today, wollastonite industry has developed by leaps and bounds, the world's main use of wollastonite is the ceramic industry, and it can be used as plastic, rubber, paint, functional fillers in paint field. At present, China's main consumption area of wollastonite is ceramic industry, accounting for 55%; Metallurgical industry accounted for 30%, other industries (such as plastic, rubber, paper, paint, welding, etc.), accounting for about 15%.

1. Ceramic industry: Wollastonite in the ceramic market is very mature, widely used in the ceramic industry as the green body and glaze, makes the green body and glaze from crack and easy break, no cracks or flaws, increase glaze surface gloss degree.

2. Functional filler: High purity wollastonite used as inorganic white pigment is widely used in coatings, can replace some of the expensive titanium dioxide.

3. Asbestos substitutes: Wollastonite powder can replace some asbestos, glass fiber, pulp, etc., mainly used in the fire board and cement materials, friction materials, indoor wall panels.

4. Metallurgical flux: Wollastonite can protect molten steel not been oxidized under molten state and high temperature, widely used in the metallurgical industry.

5. Paint: Adding wollastonite paint can improve the physical properties, durability and resistance to climate, reduce the aging of the paint.

wollastonite Grinding process

Component analysis of wollastonite raw materials

|

CaO |

SiO2 |

|

48.25% |

51.75% |

Wollastonite powder making machine model selection program

|

Specification (mesh) |

Ultrafine powder processing(20—400 mesh) |

Deep processing of ultrafine powder(600--2000mesh) |

|

Equipment selection program |

Vertical mill or pendulum grinding mill |

Ultrafine grinding roller mill or ultrafine vertical grinding mill |

*Note: select the main machine according to the output and fineness requirements

Analysis on grinding mill models

1.Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2. HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

3. HCH ultrafine grinding roller mill: ultrafine grinding roller mill is efficient, energy-saving, economical and practical milling equipment for ultrafine powder over 600 meshes.

4.HLMX ultra-fine vertical mill: especially for large-scale production capacity ultrafine powder over 600 meshes, or customer who has higher requirements on powder particle form, HLMX ultrafine vertical mill is the best choice.

Stage I: Crushing of raw materials

The large Wollastonite material is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the pulverizer.

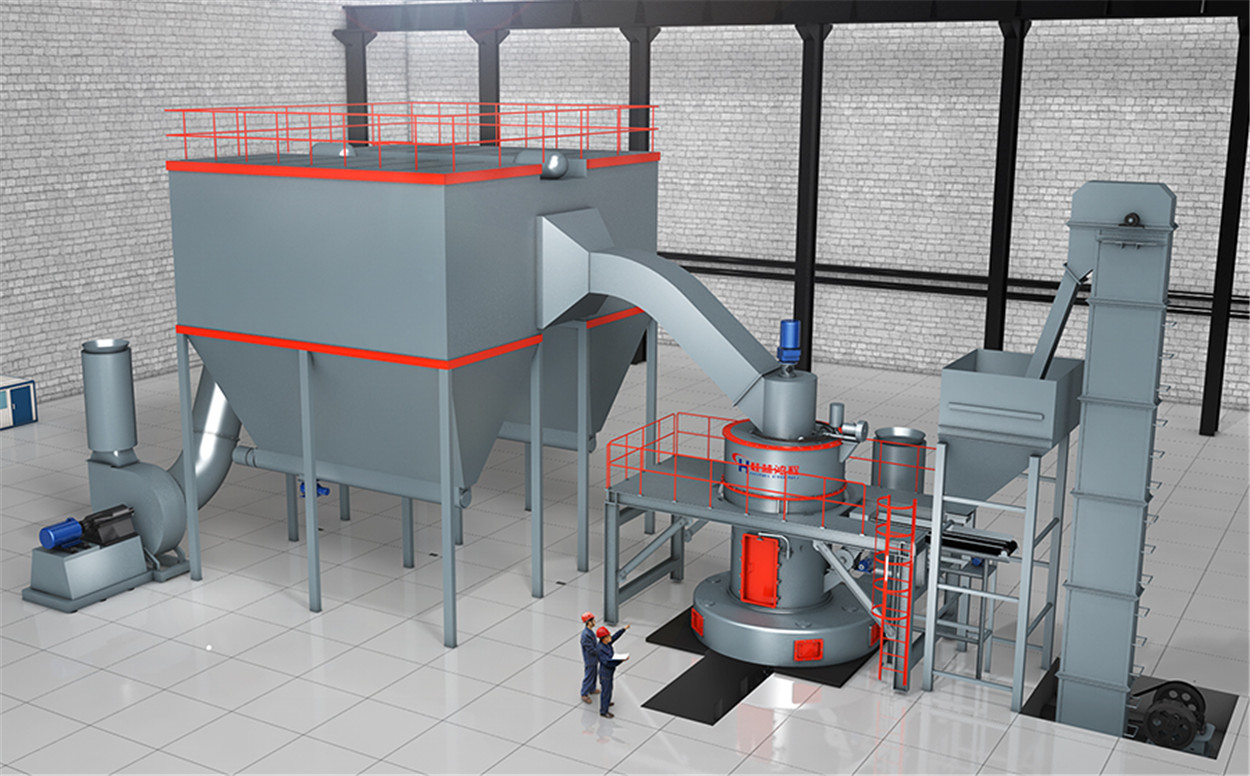

Stage II: Grinding

The crushed Wollastonite small materials are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

Stage III: Classifying

The milled materials are graded by the grading system, and the unqualified powder is graded by the classifier and returned to the main machine for re grinding.

Stage V: Collection of finished products

The powder conforming to the fineness flows through the pipeline with the gas and enters the dust collector for separation and collection. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then packaged by the powder tanker or automatic packer.

Application examples of wollastonite powder processing

Processing material: wollastonite

Fineness: 200 mesh D97

Capacity: 6-8t / h

Equipment configuration: 1 set of HC1700

Guilin Hongcheng wollastonite grinding mill has reliable quality, excellent performance, stable operation and long service life. The grinding roller and grinding ring are made of special wear-resistant materials, which are relatively wear-resistant, saving us a lot of maintenance costs. Hongcheng's R & D, after-sales, maintenance and other engineer teams are conscientious and conscientious, and wholeheartedly provide professional grinding technology and equipment for our wollastonite powder processing production line.

Post time: Oct-22-2021