Introduction to calcite

Calcite is a calcium carbonate mineral, mainly composed of CaCO3. It is generally transparent, colorless or white, and sometimes mixed. Its theoretical chemical composition is: Cao: 56.03%, CO2: 43.97%, which is often replaced by isomorphism such as MgO, FeO and MnO. Mohs hardness is 3, density is 2.6-2.94, with glass luster. Calcite in China is mainly distributed in Guangxi, Jiangxi and Hunan. Guangxi calcite is famous for its high whiteness and less acid insoluble substances in the domestic market. Calcite can also be found in the northeast of North China, but it is often accompanied by dolomite. The whiteness is generally below 94 and the acid insoluble matter is too high.

Application of calcite

1.Within 200 mesh:

It can be used as various feed additives with calcium content of more than 55.6% and no harmful components.

2.250 mesh to 300 mesh:

It is used as raw materials and internal and external wall painting of plastic factory, rubber factory, coating factory and waterproof material factory. The whiteness is above 85 degrees.

3.350 mesh to 400 mesh:

It is used for manufacturing gusset plate, downcomer pipe and chemical industry. The whiteness is above 93 degrees.

4.400 mesh to 600 mesh:

It can be used for toothpaste, paste and soap. The whiteness is above 94 degrees

5.800 mesh:

It is used for rubber, plastic, cable and PVC with whiteness above 94 degrees.

6.Above 1250 mesh

Pvc, PE, Paint, coating grade products, paper primer, paper surface coating, whiteness above 95 degrees. It has high purity, high whiteness, non-toxic, odorless, fine oil, low quality and low hardness.

Calcite Grinding process

Calcite powder making is generally divided into calcite fine powder processing (20 mesh - 400 mesh), calcite ultra-fine powder deep processing (400 mesh - 1250 mesh) and micro powder processing (1250 mesh - 3250 mesh)

Component analysis of calcite raw materials

|

CaO |

MgO |

Al2O3 |

Fe2O3 |

SiO2 |

Firing quantity |

Grinding work index (kWh/t) |

|

53-55 |

0.30-0.36 |

0.16-0.21 |

0.06-0.07 |

0.36-0.44 |

42-43 |

9.24 (Moh’s:2.9-3.0) |

Calcite powder making machine model selection program

|

Product Specification (mesh) |

80-400 |

600 |

800 |

1250-2500 |

|

Model Selection scheme |

R Series Grinding Mill HC Series Grinding Mill HCQ Series Grinding Mill HLM Vertical Mill |

R Series Grinding Mill HC Series Grinding Mill HCQ Series Grinding Mill HLM Vertical Mill HCH Series Ultra-fine Mill |

HLM Vertical Mill HCH Series Ultra-fine Mill+classifier |

HLM Vertical Mill (+classifier) HCH Series Ultra-fine Mill |

*Note: select the main machine according to the output and fineness requirements

Analysis on grinding mill models

1.Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for calcite powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2.HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

3.HCH ultrafine grinding roller mill:ultrafine grinding roller mill is efficient, energy-saving, economical and practical milling equipment for ultrafine powder over 600 meshes.

4.HLMX ultra-fine vertical mill: especially for large-scale production capacity ultrafine powder over 600 meshes, or customer who has higher requirements on powder particle form, HLMX ultrafine vertical mill is the best choice.

Stage I: Crushing of raw materials

Large calcite materials are crushed by the crusher to the feed fineness (15mm-50mm) that can enter the grinding mill.

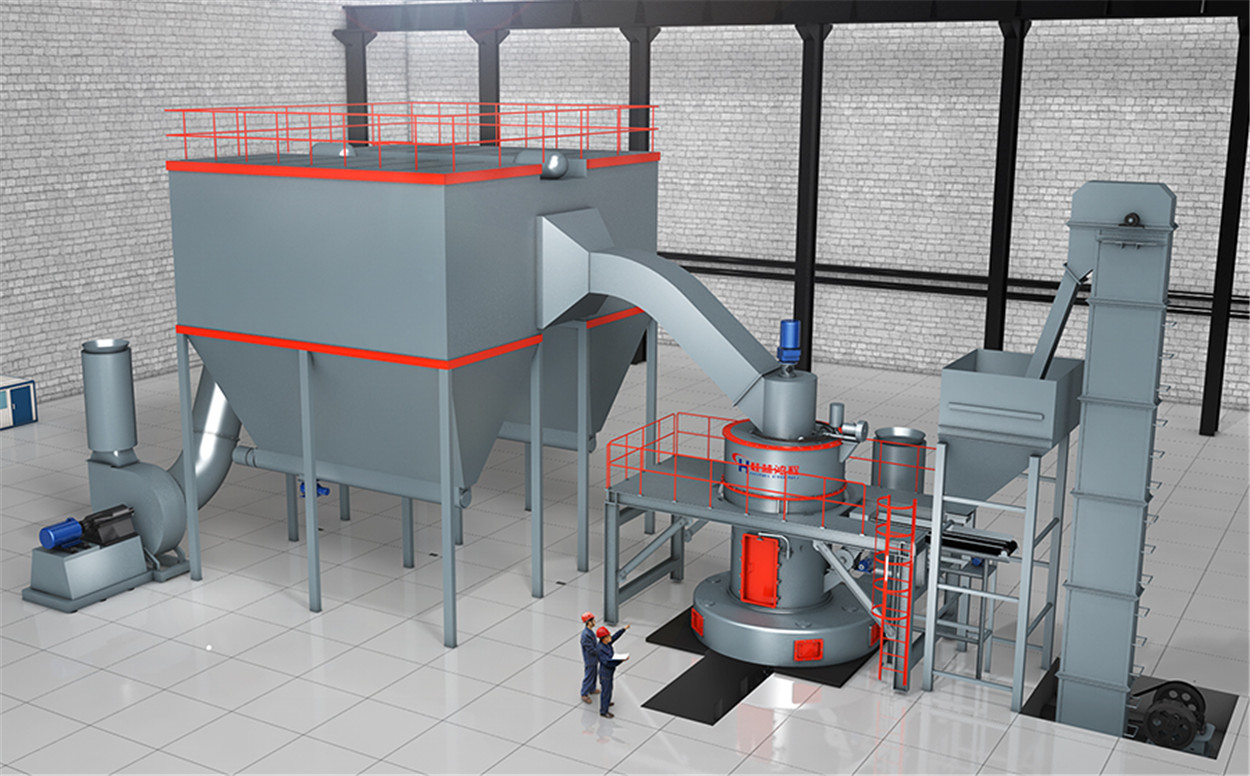

Stage II: grinding

The crushed calcite small materials are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

Stage III: Classifying

The milled materials are graded by the grading system, and the unqualified powder is graded by the classifier and returned to the main machine for re grinding.

Stage V: Collection of finished products

The powder conforming to the fineness flows through the pipeline with the gas and enters the dust collector for separation and collection. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then packaged by the powder tanker or automatic packer.

Applicable mill type:

HC Series large pendulum grinding mill(It is aimed at coarse powder below 600 mesh, with low equipment investment cost and low energy consumption)

HLMX Series superfine vertical grinding mill(Large scale equipment and high output can meet large-scale production. The vertical mill has high stability. Disadvantages: high equipment investment cost.)

HCH ring roller ultrafine mill(The production of ultra-fine powder has the advantages of low energy consumption and low equipment investment cost. The market prospect of large-scale ring roller mill is good. Disadvantages: low output.)

Application examples of calcite powder processing

Processing material:calcite

Fineness:325mesh D97

Capacity:8-10t/h

Equipment configuration:1set HC1300

For the production of powder with the same specification, the output of hc1300 is almost 2 tons higher than that of the traditional 5R machine, and the energy consumption is low. The whole system is fully automatic. Workers only need to operate in the central control room. The operation is simple and saves labor cost. If the operating cost is low, the products will be competitive. Moreover, all the design, installation guidance and commissioning of the whole project are free, and we are very satisfied.

Post time: Oct-22-2021