Introduction to Aluminum ore

Aluminum ore can be economically extracted a natural aluminum ore, bauxite is the most important one. Alumina bauxite is also known as bauxite, the main component is alumina oxide which is hydrated alumina containing impurities, is an earthy mineral; white or gray, shows in brownish yellow or pink color because of iron contained. Density is 3.9~4g/cm3, hardness 1-3, opaque and brittle; insoluble in water, soluble in sulfuric acid and sodium hydroxide solution.

Application of Aluminum ore

Bauxite is rich in resources, needed for many industries; therefore, it is a very popular non-metallic material, and the reason why it has been generally welcomed, mainly because it is very promising in the industrial field.

1. Aluminum industry. Bauxite used in national defense, aerospace, automotive, electrical, chemical and other daily necessities industries.

2. Casting. Calcined bauxite is processed into a fine powder for casting after the mould and used in military, aerospace, communications, instrumentation, machinery and medical equipment sectors.

3. For refractory products. High calcined bauxite refractoriness can reach up to 1780 °C, chemical stability, good physical properties.

4. Aluminosilicate refractory fibers. With several advantages such as light weight, high temperature resistance, good thermal stability, low thermal conductivity, small heat capacity and resistance to mechanical vibration and so on. Can be used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, nuclear, national defense and other industries.

5. Raw material of magnesia and bauxite, added with appropriate binder, can be used for casting overall cylinder liner of molten steel ladle with very good results.

6. The manufacture of bauxite cement, abrasive materials, various compounds can be made of aluminum bauxite in ceramic industry and the chemical industry.

Process flow of Aluminum ore pulverization

Aluminum ore ingredient analysis sheet

|

Al2O3、SiO2、Fe2O3、TiO2、H2O+ |

S、CaO、MgO、K2O、Na2O、CO2、MnO2、Organic matter、Carbonaceous etc |

Ga、Ge、Nb、Ta、TR、Co、Zr、V、P、Cr、Ni etc |

|

Over 95% |

Secondary ingredients |

Trace ingredients |

Aluminum ore powder making machine model selection program

|

Specification |

Deep processing of fine powder(200-400mesh) |

|

Equipment selection program |

Vertical grinding mill and Raymond grinding mill |

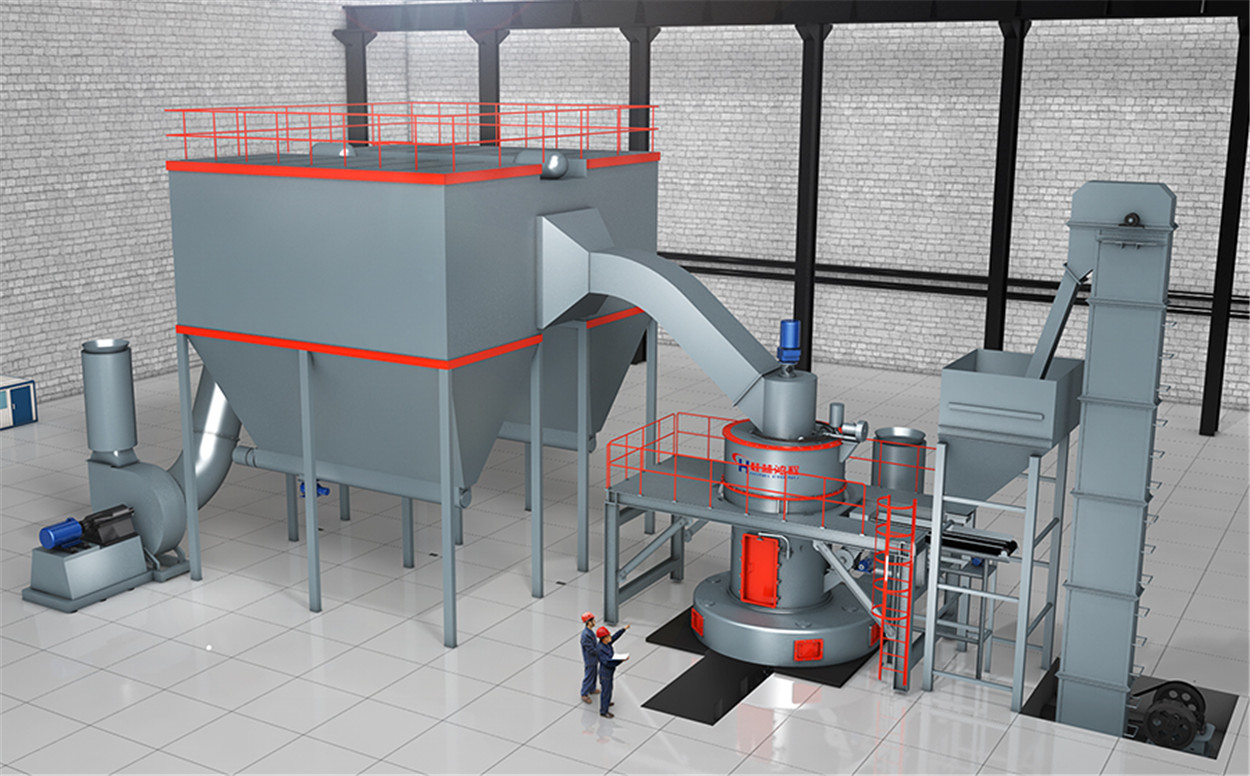

Analysis on grinding mill models

1. Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for aluminum ore powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2.HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

Stage I: Crushing of raw materials

The large Aluminum ore material is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the grinding mill.

Stage II: Grinding

The crushed Aluminum ore small materials are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

Stage III: Classifying

The milled materials are graded by the grading system, and the unqualified powder is graded by the classifier and returned to the main machine for re grinding.

Stage V: Collection of finished products

The powder conforming to the fineness flows through the pipeline with the gas and enters the dust collector for separation and collection. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then packaged by the powder tanker or automatic packer.

Application examples of aluminum ore powder processing

Model and number of this equipment: 1 set of HC1300

Processing raw material: Bauxite

Fineness: 325 mesh D97

Capacity: 8-10t / h

Equipment configuration: 1 set of HC1300

For the production of powder with the same specification, the output of HC1300 is almost 2 tons higher than that of the traditional 5R machine, and the energy consumption is low. The whole system is fully automatic. Workers only need to operate in the central control room. The operation is simple and saves labor cost. If the operating cost is low, the products will be competitive. Moreover, all the design, installation guidance and commissioning of the whole project are free, and we are very satisfied.

Post time: Oct-22-2021