Hordhac Dolomite

Dolomite waa nooc ka mid ah macdanta karbohaydrayt, oo ay ku jiraan ferroan-dolomite iyo mangan-dolomite.Dolomite waa macdanta ugu weyn ee dhagaxa dolomite.Dolomite saafi ah waa caddaan, qaar ayaa laga yaabaa inay cawlaan haddii ay bir ku jirto.

Codsiga dolomite

Dolomite waxaa lagu dabaqi karaa qalabka dhismaha, dhoobada, dhalada, walxaha dib-u-celinta, kiimikada, beeraha, ilaalinta deegaanka iyo beeraha badbaadinta tamarta.Dolomite waxaa loo isticmaali karaa sida walxaha aasaasiga ah ee refractory, qulqulka foornada qarxinta, bacriminta calcium magnesium phosphate, iyo walxaha sibidhka iyo warshadaha dhalooyinka.

Habka wax shiididda Dolomite

Falanqaynta qaybaha alaabta ceeriin ee dolomite

| CaO | MgO | CO2 |

| 30.4% | 21.9% | 47.7% |

Fiiro gaar ah: waxay inta badan ka kooban tahay wasakh sida silikoon, aluminium, birta iyo titanium

Budada Dolomite samaynta barnaamijka xulashada mashiinka

| Tilmaamaha alaabta | Budada khafiifka ah (80-400 mesh) | Habka qoto dheer ee aadka u fiican (400-1250 mesh) | Budada Micro (1250-3250 mesh) |

| Qaabka | Raymond Mill, warshad toosan | Warshadaynta aadka u fiican, mishiinka aadka u fiican | |

*Fiiro gaar ah: dooro mashiinka ugu muhiimsan si waafaqsan shuruudaha wax soo saarka iyo ganaaxa

Falanqaynta moodooyinka shiididda

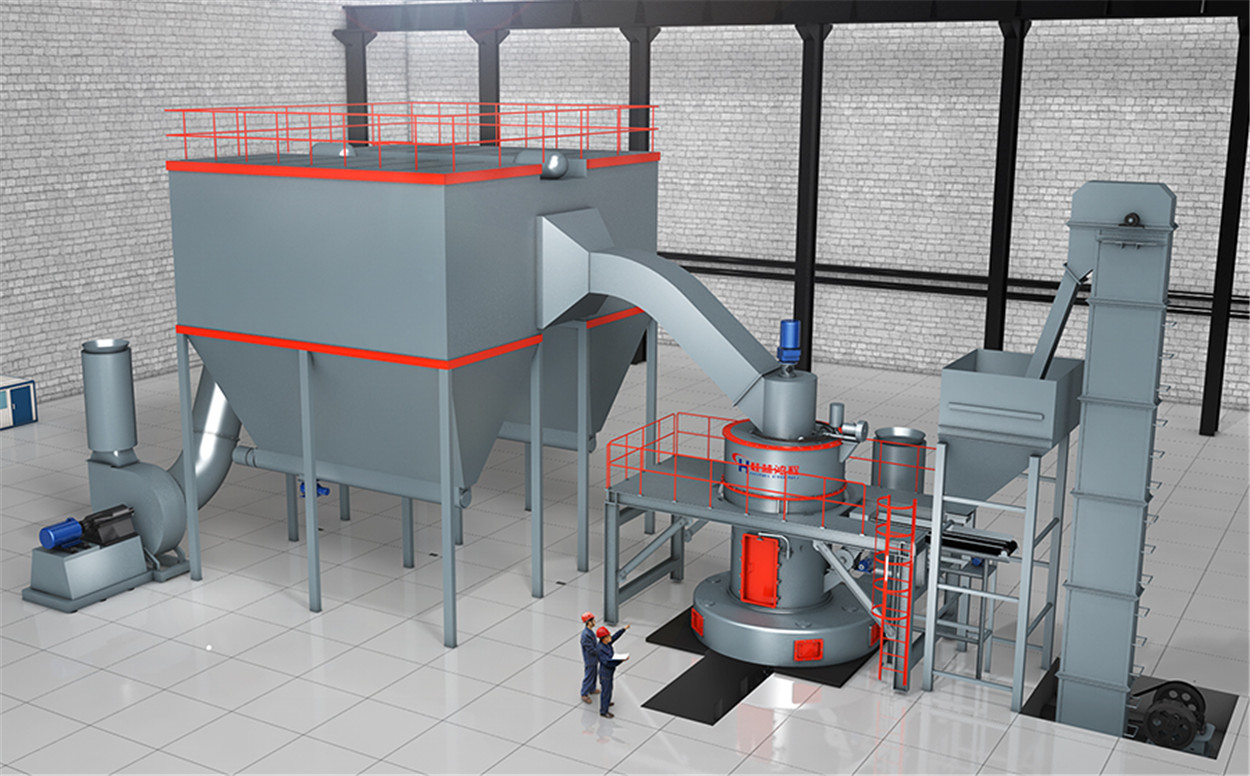

1. HC Taxanaha Shiidada Mill: kharashka maalgashiga hooseeya, awoodda sare, isticmaalka tamarta yar, hawlgal joogto ah, buuq yar.Khasaaraha: Awoodda halliga ah oo hooseysa, ma aha qalab ballaaran.

2. HLM Tooska ah Mill: qalab ballaaran, awood sare, hawlgal joogto ah.Khasaaraha: kharashka maalgashiga oo sarreeya.

3. HCH Ultra-fine Mill: kharash yar oo maalgashi, isticmaalka tamarta yar, kharash badan oo waxtar leh.Khasaaro: Awood yar, qalabyo badan ayaa loo baahan yahay si loo dhiso khadka wax soo saarka.

4.HLMX Ultra-fine Vertical Mill: awood u leh inay soo saarto 1250 mesh budada ultra-fine, ka dib markii lagu qalabeeyay nidaam kala-saar heerar kala duwan ah, 2500 mesh micro budo ah ayaa la soo saari karaa.Qalabku wuxuu leeyahay awood sare, qaab wax soo saar wanaagsan, waa xarun ku habboon habaynta budada tayada sare leh.Khasaaro: kharashka maalgashiga oo sarreeya.

Marxaladda I: Burburinta alaabta ceeriin

Walxaha waaweyn ee dolomite-ka waxaa lagu jajabiyaa jajabiyaha si ay u nuugaan feerka (15mm-50mm) kaas oo geli kara mashiinka wax lagu shiidayo.

Marxaladda II: Shiidida

Walxaha yar yar ee dolomite-ka ah ee la jajabiyey ayaa wiishku u diraa hopper-ka kaydinta, ka dibna waxa loo diraa qolka wax lagu shiida ee shiidka si siman iyo qiyaas ahaan feediyaha si loo shiido.

Marxaladda III: Kala saaridda

Alaabta la shiiday waxaa lagu qiimeeyay nidaamka darajooyinka, iyo budada aan u qalmin waxaa lagu qiimeeyay kala soocida oo lagu soo celiyaa mashiinka weyn si dib loogu shiido.

Marxaladda V: Ururinta alaabta la dhammeeyey

Budada u hoggaansamaya ganaaxa waxay ku socotaa dhuunta gaaska waxayna gashaa boodhka ururiyaha si loo kala saaro oo loo ururiyo.Budada dhammaatay ee la ururiyay waxa loo diri silo alaabta la dhammeeyay iyada oo loo sii marinayo aalladda gudbinta iyada oo la marsiinayo dekedda, ka dibna lagu baakadeeyo booyada budada ama baakadaha tooska ah.

Tusaalooyinka codsiga ee habaynta budada dolomite

Mashiinnada Dolomite: Millilaha rullaluistemadka toosan, Milla Raymond, warshad ultra-fine ah

Qalabka farsamaynta: Dolomite

Ganaaxa: 325 mesh D97

Awoodda: 8-10t / saac

Qaabaynta qalabka: 1 set oo ah HC1300

Qalabka Hongcheng oo dhamaystiran waxa uu leeyahay nidaam is haysta, dhul yar oo sagxadda ah waxana uu kaydiyaa kharashka dhirta.Nidaamka oo dhan si buuxda ayaa loo kantaroolaa, waxaana lagu dari karaa nidaamka la socodka fog.Shaqaaluhu waxay u baahan yihiin oo kaliya inay ka shaqeeyaan qolka kontoroolka dhexe, kaas oo fudud in lagu shaqeeyo oo badbaadiya kharashka shaqada.Waxqabadka mishiinka sidoo kale waa mid deggan oo wax soo saarku wuxuu gaarayaa rajada.Dhammaan naqshadeynta, hagidda rakibidda iyo hawlgelinta mashruuca oo dhan waa bilaash.Tan iyo markii la istcimaali jiray shiididda Hongcheng, wax-soo-saarkayaga iyo waxtarkayaga waa la wanaajiyey, aad baannu ugu qanacsannahay.

Waqtiga boostada: Oct-22-2021