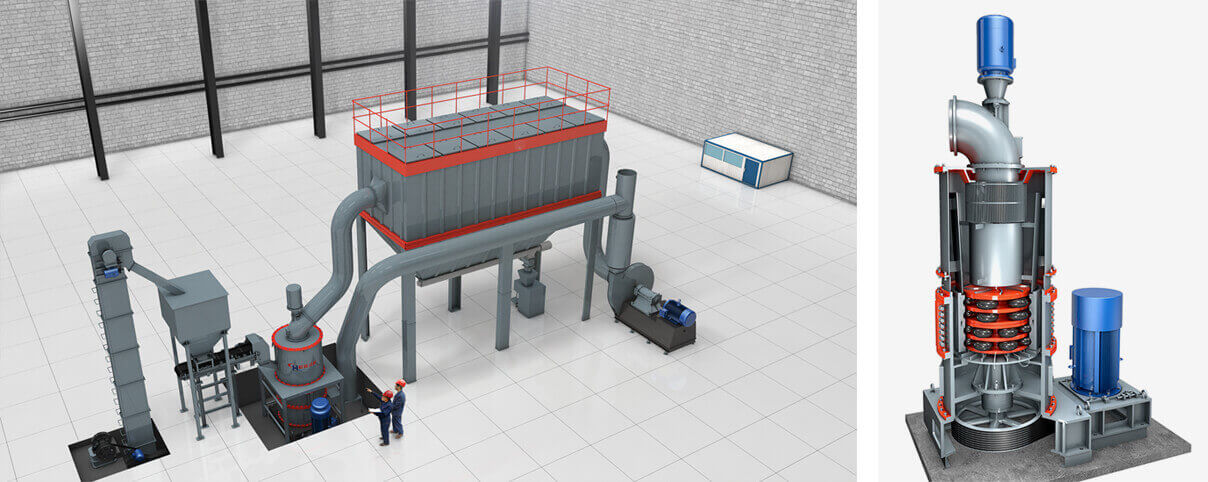

Saamiga burburinta sare.Cabbirka walxaha quudinta ee ka yar 10mm waxaa loo habayn karaa si fiican<10μm (97% dhaaf).iyo ganaaxa ugu dambeeya ee ka yar 3um wuxuu ahaa qiyaastii 40%, taas oo gacan ka geysata aag gaar ah oo gaar ah.

faham

U BAAHAN XAL?Wixii macluumaad dheeraad ah oo shiididda ama codsiga xigashada fadlan nala soo xiriir.

Weydiinnala soo xiriir

Ku soo dhawoow Guilin HongchengGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Taleefanka:86-0773-3568321

- Cinwaanka:Beerta Warshadaha ee Yangtang Shanshui, Aagga Horumarinta Dhaqaalaha ee Xicheng, Guilin City, Gobolka Guangxi, Shiinaha

- Iimayl:hcmkt@hcmilling.com

© Xuquuqda daabacaadda - 2010-2023: Dhammaan xuquuqaha way xifdisan yihiin.Alaabooyinka Kulul - Khariidadda goobta

Batroolka Coke Roller Mill, Milkiilaha Mille, Ultra Fine Mill, Ultra Fine shiididda Mill, Shidida Dhuxusha, Warshadda Rinjiga Rinjiga Burada Ka Soo Qaada Shiineeska,

Batroolka Coke Roller Mill, Milkiilaha Mille, Ultra Fine Mill, Ultra Fine shiididda Mill, Shidida Dhuxusha, Warshadda Rinjiga Rinjiga Burada Ka Soo Qaada Shiineeska,