Girazi remarara imhando yemarara emumba, kuvepo kwayo hakungokonzerese kukuvadza uye kusagadzikana kune kugadzirwa kwevanhu nehupenyu, asiwo kunounza kusvibiswa kune zvakatipoteredza, kunotora ivhu rakakosha, uye kunowedzera mutoro kwezvakatipoteredza.Zvinofungidzirwa kuti China inogadzira anenge 3.2 miriyoni matani emarara egirazi gore rega rega, inoverengera ingangoita 2% yehuwandu hwese hwemasisita marara.Nekuvandudzwa kwesimba renyika rakazara uye nekuvandudzwa kwemararamiro evanhu, huwandu hwegirazi remarara hwawedzerawo.Panyaya yekudzokorodza uye kushandiswa kwemagirazi emarara, dzimwe nyika dzakabudirira muUnited Kingdom neUnited States dzakawana mhedzisiro inoshamisa.Nyika dzeEurope neAmerica dzakabudirira kushandisa girazi remarara muzvirongwa zvekuvaka, inova nzira inoshanda yekushandisa yakawanda yemarara.Nekuti marudzi ese emarara egirazi haadi kurongedzwa, hapana chinodiwa cheruvara.Semuenzaniso, tsvina yegirazi inogadziriswa sechivakwa chekushongedza zvinhu muMosaic.Semugadziri wemarara egirazi chigayo, tsvina yegirazi mill inogadzirwa neHCM Machinery inopa yakanaka midziyo yekubatsira kudzokorodza kwemarara girazi.Nhasi, isu tichasuma maitiro ekugadzira emarara girazi recycling girazi Mosaic.

1. Beneficiation of phosphate rock: Beneficiation of phosphate rock inhanho yekutanga mukugadzirisa phosphate rock, iyo ine chinangwa chekuparadzanisa zvicherwa zvinobatsira kubva kune tsvina yephosphate rock nenzira dzemuviri nemakemikari.Nzira dzakajairika dzekubatsiridza dzinosanganisira kupatsanurwa kwegiravhiti, flotation uye kupatsanurwa kwemagineti.Kupatsanurwa kwegiravhiti kunoshandisa density mutsauko wemaminerari muore yekuparadzanisa, flotation inoshandisa buoyancy mutsauko wemaminerari muore yekuparadzanisa, uye kupatsanurwa kwemagineti kunoshandisa musiyano wemagineti wemaminerari muore yekuparadzanisa.

2. Kupwanya nekukuya phosphate rock: phosphate rock mushure mebeneficiation, inoda kupwanyika uye kukuya kurapwa, kuitira kuti zvive nani kusunungura zvicherwa zvinobatsira mumatombo.Kupwanya kunowanzo shandiswa jaw crusher, cone crusher uye zvimwe midziyo yekupwanya phosphate rock kuita yakakodzera particle size.Kukuya iko kushandiswa kwechigayo chikuru kugadzira uye kugadzirisa phosphate poda muchina kukuya pfumbu yakapwanyika ore, kuti ikwane zvinodiwa fineness zvinodiwa.

3. Leaching of phosphate rock: Leaching inhanho inokosha mukugadzirisa phosphate rock, kuburikidza iyo inobatsira zvinhu zvakadai sephosphate inogona kunyungudutswa kubva mumatombo.Nzira dzinowanzo shandiswa leaching dzinosanganisira acid leaching, alkali leaching uye oxidation leaching.Acid leaching inoshandisa acidic solution yekunyungudutsa phosphate, alkaline leaching inoshandisa alkaline solution kunyungudutsa phosphate, uye oxidative leaching inoshandisa oxidizing agent kunyungudutsa phosphate.

4. Kunaya nekusefa kwefosfate ores: Mushure mekunyunguduka, mushonga wezvinhu zvinobatsira zvakaita sefosfate zvinoda kunaya nekusefa kuti zviparadzanise zvigadzirwa zvefosfate zvakasimba.Kunaya kwemvura ndiko kushandiswa kweiyo precipitating agent kushandura phosphate chikamu chemushonga kuti ive yakasimba precipitate, uye kusefa ndiko kupatsanurwa kweiyo sediment kubva kune mhinduro nekusefa michina.

5. Kuomesa uye kunyungudutswa kwedombo rephosphate: Pashure pokunge sediment yapepetwa, inoda kuomeswa uye kunyudzwa kuti iwane chigadzirwa chephosphate chapera.Kuomesa iko kushandiswa kwemidziyo yekuomesa kuburitsa mvura mumatope, uye sinter ndiko kuomeswa kweiyo sediment pane yakanyanya tembiricha sintering, zvekuti inogadzira dense phosphate particles.

6. Phosphate ore tailings treatment: phosphate ore processing process ichabudisa humwe huwandu hwemaswe, miswe ine zvicherwa zvisina kubviswa uye tsvina.Kuti kuderedze kusvibiswa kwezvakatipoteredza uye kutambisa zviwanikwa, misarira inofanirwa kurapwa.Iyo yakajairika tailings nzira dzekurapa dzinosanganisira tailings stacking, tailings recycling uye tailings yakazara kushandiswa.

Iyo nzira yekugadzira yemarara girazi rekudzokorodza girazi Mosaic: sintering nzira uye nzira yekunyungudusa inowanzoshandiswa, uye nzira yekugadzira ye sintering nzira uye ceramic Mosaic zvakangofanana.Iyo huru yekugadzira maitiro ndeyekugaya girazi remarara kuburikidza nemarara egirazi chigayo kuti asangane nezvinodiwa zvehupfu hwegirazi, uye wobva wawedzera imwe huwandu hwekunamira mumiririri (inorganic kana organic can) uye mumiriri wemavara kana decolorizing agent, ine mixer kuti isanganise kuita yunifomu komboni.Musanganiswa unodzvanywa mumhando dzakasiyana dzejometri nenzira yakaoma yekutsikirira, uye muviri wakaomeswa unotumirwa kuchoto che roller, push plate kiln uye tunnel kiln ine tembiricha ye800-900 madhigirii Celsius yekupisa.Kazhinji, inogara mu sintering tembiricha zone kwemaawa 1.5-2.5.Zvigadzirwa zvekutonhodza kubva muchoto kuti zviongororwe, kuiswa, kuomeswa, kuongororwa, kurongedza, kuchengetedza kana fekitori, zvigadzirwa zvisina kukodzera zvinodzokororwa.Iyo nzira yekunyunguduka yakavakirwa pamarara girazi (huwandu hwevanhu 25-60%) sechinhu chikuru mbishi, ichiwedzera imwe huwandu hwesilica jecha, feldspar, limestone, soda ash uye emulsion agent, coloring agent kuburikidza nemarara girazi kugaya. meshini kuita yunifomu inoenderana nehupfu, uyezve mune yakanyanya tembiricha yekunyunguduka (tembiricha yekunyunguduka i1400-1500) kunyungudika kuita yunifomu yegirazi mvura.Iyo girazi mvura inoyerera ichipinda mucalender uye inotsikirirwa mugirazi bhuroka yeimwe saizi uye chimiro, iyo inotumirwa kune annealing kiln.Zvigadzirwa zvakavharwa zvinogona kuchengetwa kana kuendeswa mushure mekuongororwa, kuiswa uye kurongedza.

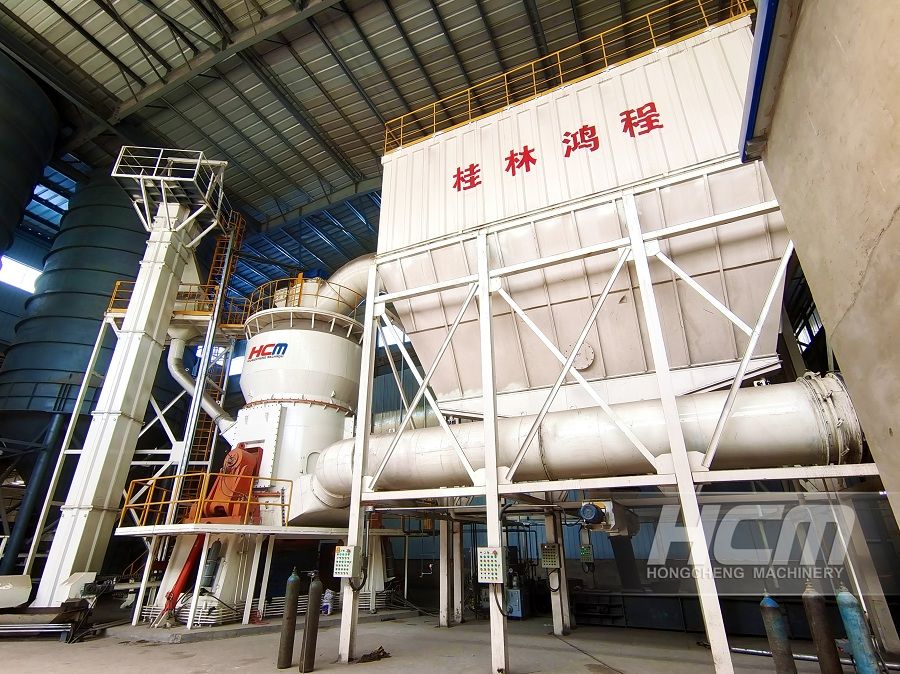

Marara egirazi kudzokorodza Magirazi egirazi anobva pakukuya marara girazi kuita upfu hwegirazi.Waste glass mill chinhu chekugadzira chekugadzira girazi poda.Iyo tsvina yegirazi gayo inogadzirwa neHCM Machinery has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Nguva yekutumira: Jan-08-2024