The large-scale recycling of construction waste into various renewable products to realize green recycling can not only turn waste into treasure and generate economic benefits, but also reduce the exploitation of sand and stone natural resources to avoid new environmental problems. Some companies and research institutions in China, including downstream customers of HCMilling(Guilin Hongcheng), have achieved certain results in using recycled micro powder as a concrete admixture. Can construction waste be treated with a vertical mill? The manufacturer of Vertical Mill -HCMilling(Guilin Hongcheng) utilizes the advantages of large-scale and efficient energy conservation of vertical mills, using construction waste as raw material. After grinding, two types of recycled building materials can be produced simultaneously. One type can be used as recycled fine aggregate for concrete and mortar, and the other type can be used as a substitute for mineral admixtures for concrete or as fine aggregates. Successful operation cases have been obtained. Below is a detailed introduction to the process flow of construction waste vertical mill.

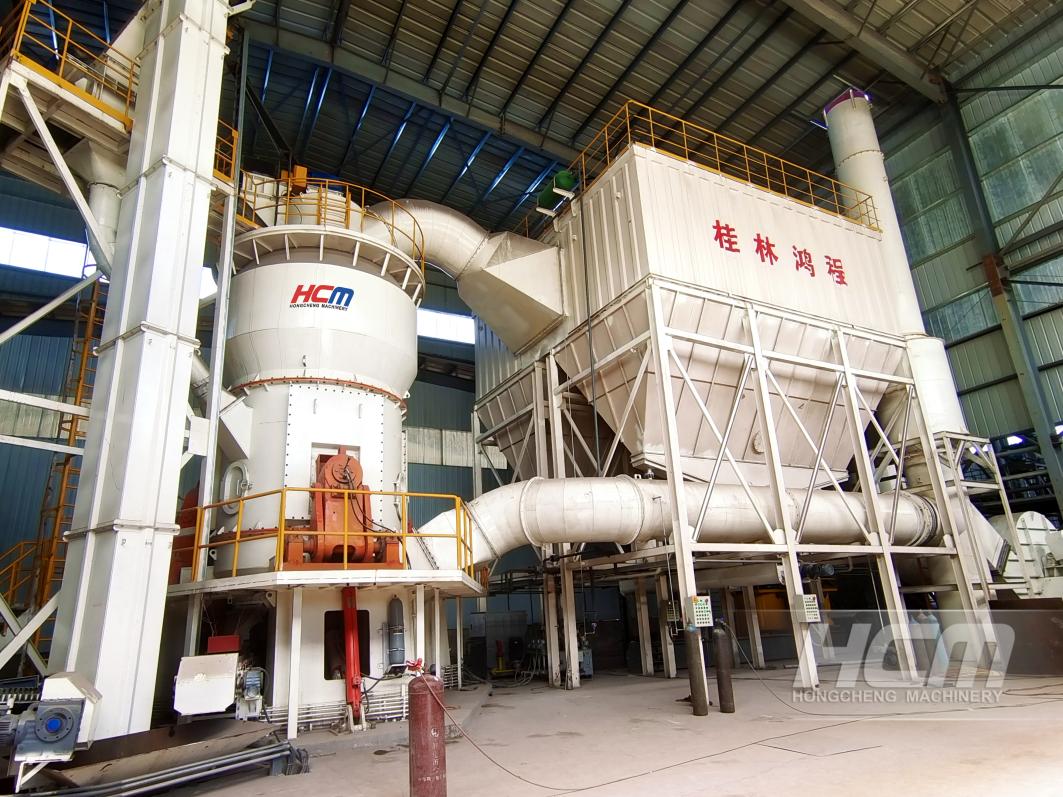

Faced with the diversified treatment requirements of construction waste, it is necessary to produce both recycled micro powder and recycled sand products. To achieve multi-purpose grinding, it is not only necessary to design and improve the mill structure, but also to further optimize the resource utilization process. According to the requirements of construction waste treatment, the process flow of construction waste vertical mill is shown in the above figure: the construction waste particles (with a particle size of ≤ 20 mm) processed through sorting, crushing, iron removal, and impurity removal are transported to the construction waste raw material warehouse using a bucket elevator. A belt scale is designed below the warehouse, and the materials are measured and sent to the construction waste vertical mill through a lock air feeder for grinding. The micro powder products are selected by the powder selection machine and collected by a bag dust collector, Sent to the regenerative micro powder silo through conveying equipment (capable of sorting regenerated micro powder with a specific surface area of 400-800 m/kg); At the same time, the sand powder mixture collected by the grinding apron type aggregate device can obtain ≤ 5mm recycled sand products after subsequent screening. The recycled micro powder and recycled sand produced by this process can be used for the production of recycled building materials (recycled concrete, recycled mortar, etc.).

Most of the raw materials for construction waste vertical mill are composed of clay bricks, cement stone, crushed mortar, limestone (with a small amount of cement stone on the surface), etc. The first three have a certain hydration activity after grinding, and limestone can serve as ultrafine filler after grinding. The successful application of HCMilling(Guilin Hongcheng) HLM construction waste vertical grinding mill to produce regenerated micro powder from construction waste provides a new approach for the resource utilization of construction waste.

If you would like to learn more about the application details of construction waste vertical mill, please contact HCMilling(Guilin Hongcheng) for detailed quotation details of vertical mills.

Post time: May-06-2023