Pre- slaker

Tasked with stirring and conveying, Pre-slaker is comprised of horizontal single shaft plus wear-resistant blade. The blade employs removable alloy wear-resistant bush, which is durable and wear-free. The blades are arranged in a spiral formation around the main axis, whose special structure leads to thorough agitation and calcium oxide and water being chemically reacted.

Pulverizer

Similar to pre-slaker in terms of structure and features, the pulverizer employs three-stage spiral and its effective working volume is about 4-8 times of that of the pre-slaker. The lime is more thoroughly slaked with the combined use of the pulverizer and the pre-slaker. Materials that are not completely slaked in the pre-slaker is fully agitated in the pulverizer to accelerate the slaking. It is characterized by slaking at constant temperature, small floor area, long effective length and thorough slaking.

Homogenizer

Homogenizer functions as an extension of pulverizer. Connected with the three-stage slaker, homogenizer and plays the role of slaking, aging and cooling. It can effectively tackle the issue of improper water amount and plays a special role in cooling the Calcium Hydroxide before it enters the classifier . Based on the temperature of the lime and Its fluidity of the pulverizing process, the homogenizer is cooling the material by fully releasing the steam, which makes the processing more smooth and the water amount more proper.

Water Spray Dedusting Device

Pulse bag filter dedusting combined with water spay dedusting to ensure that the dust emission is up to the standard. Making full use of the waste heat to heat the digestion water to about 80 ℃ to promote lime digestion.

Cylinder Sieve

It separates the burnt lime particles.

Pulse Dust Collector

It eliminates the excess steam generated by elevator, cylinder sieve and semi-finished product silo.

Control System

Mechanical automatic control, PLC automatic control and online smart monitoring.

HC Series Calcium Hydroxide / Calcium Oxide Mill And For HLMZ Slag Fine Grinding Vertical Mill

HC series calcium hydroxide / calcium oxide mill and HLMZ fine grinding slag vertical mill for are super large calcium hydroxide production equipment are independently developed by HCM with a number of patented technologies to its credit, which are highly energy-efficient. With output as high as 30 tons / hour, they can live up to national industrial standard, meeting the increasingly

expanding industrial production demand, filling the void of large-scale calcium hydroxide production equipment in China. Characterized by vertical structure, small floor area, ow maintenance cost, low noise and environment-friendly, its performance is markedly improved in terms of output or unit energy consumption, which leads the industry.

Features:

1.It shares the functionality and performance of powder separator.

2.It is a combination of powder selection, grinding mill, which can replace the traditional ball mill. It is a multi purpose machine of energy consumption and low investment.

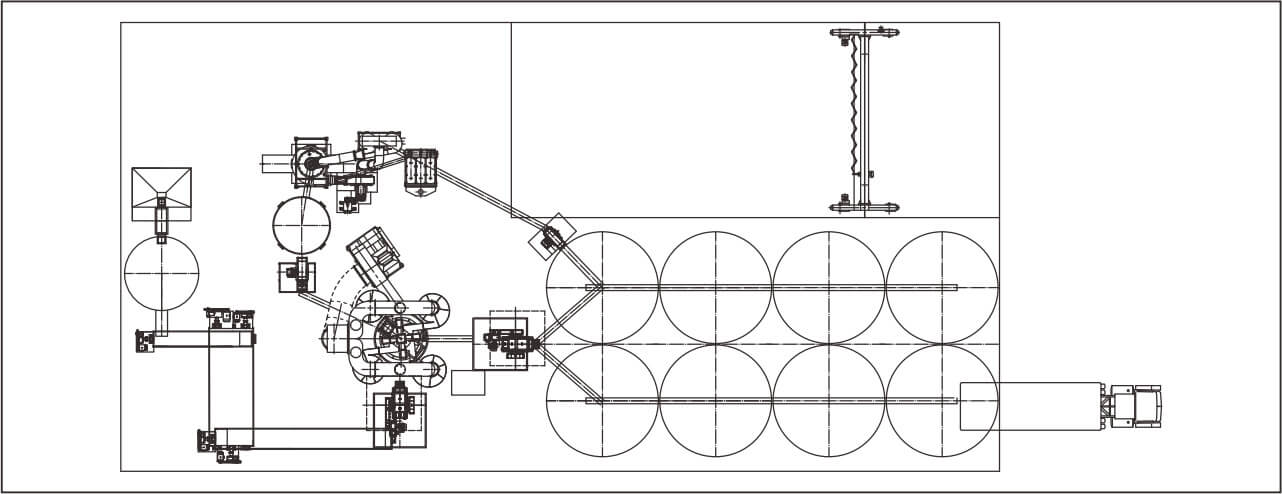

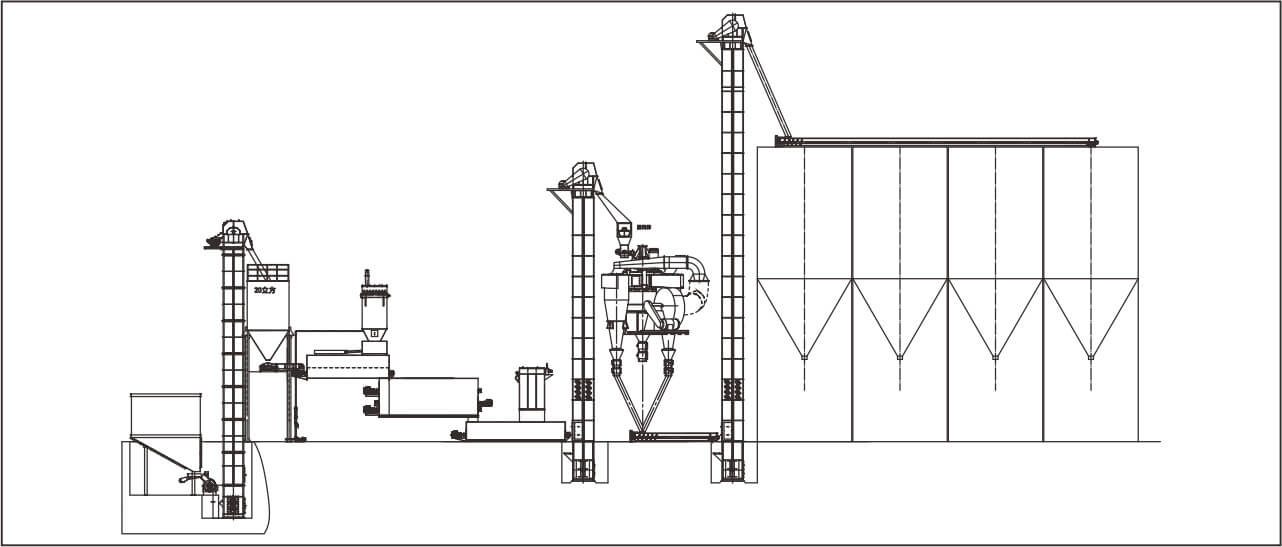

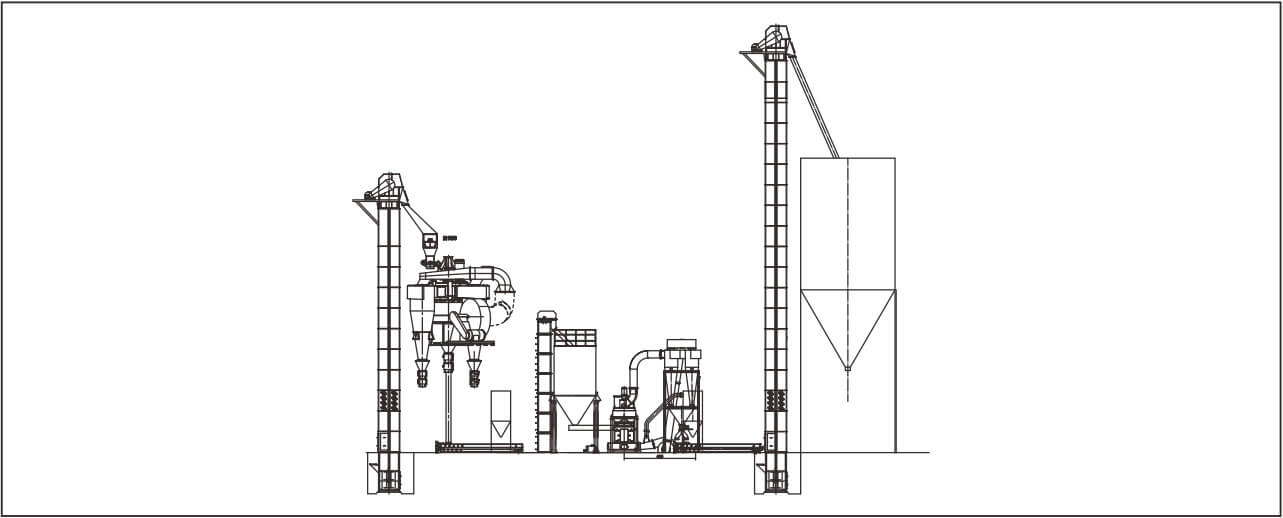

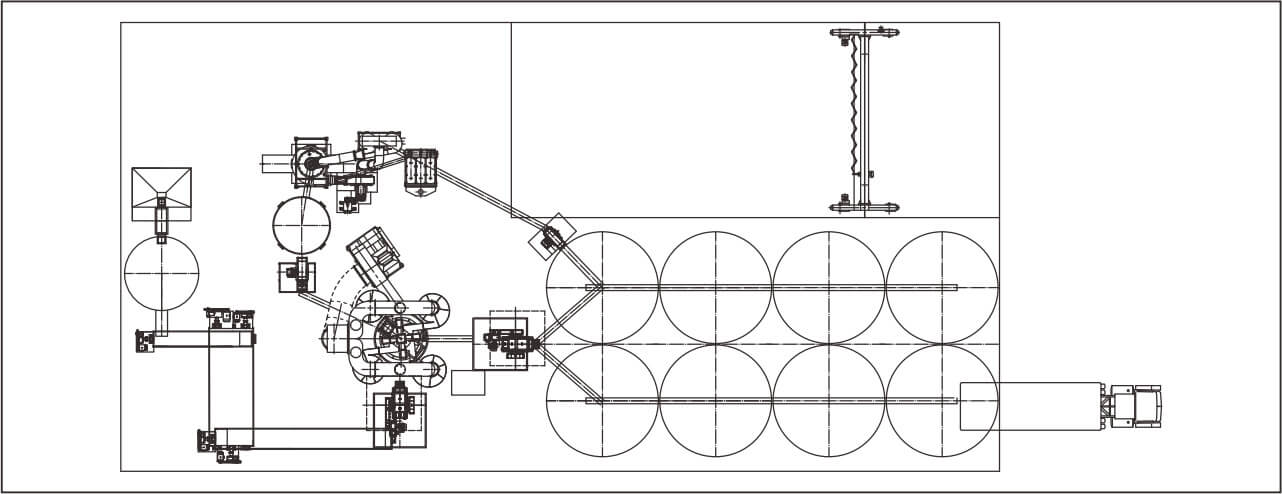

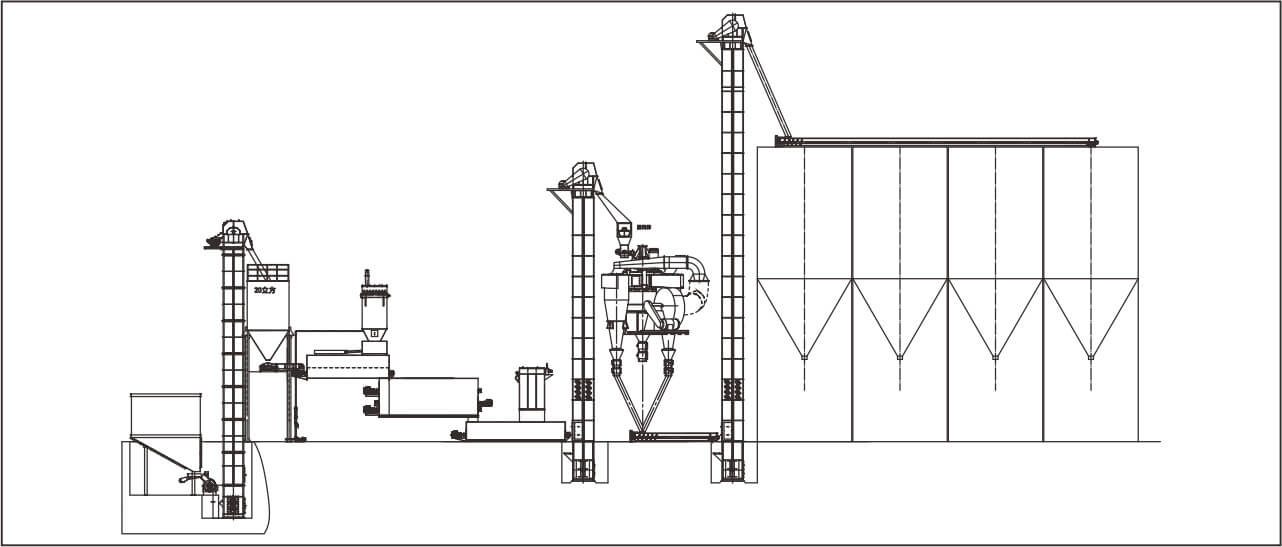

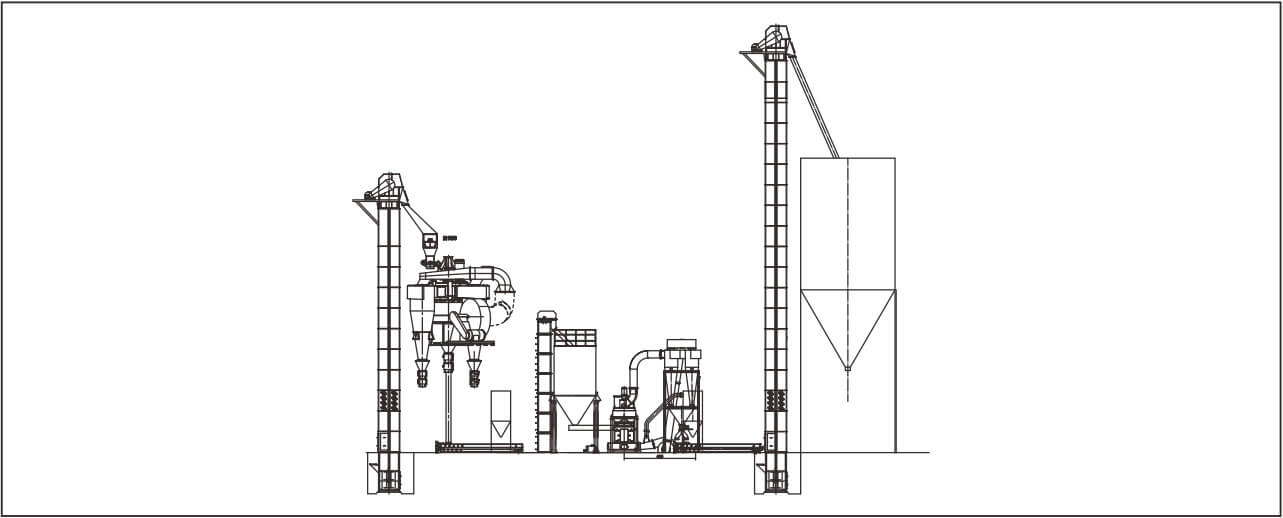

Calcium Hydroxide Production Line Layout Drawing

Product detail pictures:

Related Product Guide:

Manufacturer for Power Plant Desulphurization Process - CaIcium Hydroxide Production Line – HCM, The product will supply to all over the world, such as: , , ,