Cov khoom kawg muaj qhov ruaj khov zoo.Lub sij hawm luv luv ntawm cov khoom siv los ua hauv av tuaj yeem ua kom pom txawm tias cov duab zoo nkauj thiab zoo heev fluidity.Ob peb cov ntsiab lus hlau yog yooj yim tshem tawm kom lav siab whiteness thiab purity.

nkag siab

YUAV TSUM TAU TXAIS?Yog xav paub ntxiv kev sib tsoo zeb cov ntaub ntawv lossis cov lus thov thov hu rau peb.

Kev nugtiv tauj peb

Txais tos rau Guilin HongchengGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Xov tooj:86-0773-3568321 ib

- Chaw nyob:Yangtang Shanshui Industrial Park, Xicheng Economic Development Zone, Guilin City, Guangxi Province, Suav

- E-mail:hcmkt@hcmilling.com

© Copyright - 2010-2023 : All Rights Reserved.Cov khoom kub - Daim ntawv qhia chaw

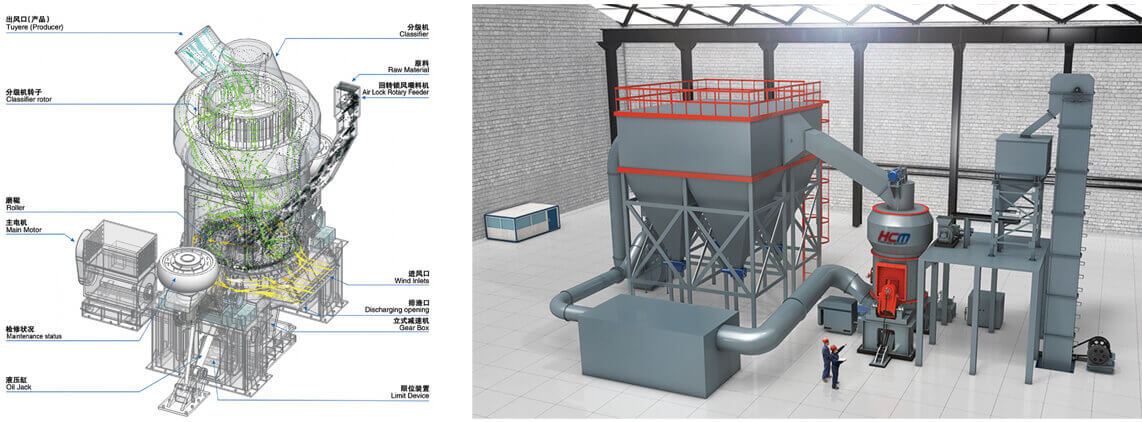

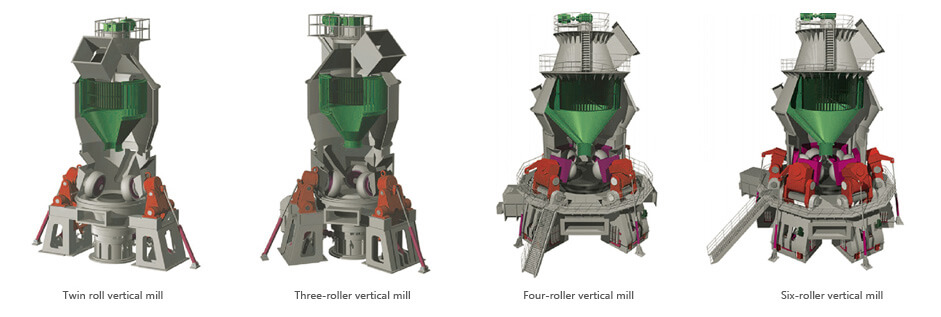

Ultra Fine Sib Tsoo Mill, Coal Grind, Zeb Grinder, Ultra Fine Mill, Petroleum Coke Vertical Roller Mill, Hmoov Xim Sib Tsoo Zeb Los ntawm Tuam Tshoj tus neeg muag khoom,

Ultra Fine Sib Tsoo Mill, Coal Grind, Zeb Grinder, Ultra Fine Mill, Petroleum Coke Vertical Roller Mill, Hmoov Xim Sib Tsoo Zeb Los ntawm Tuam Tshoj tus neeg muag khoom,